Welcome to the ASU Core Facilities Newsletter. We are ready to support all your research goals. Please follow our LinkedIn page for additional resources and community information.

Batteries

ASU is working to increase the power density of batteries while decreasing battery size through new materials and process and manufacturing techniques to improve the future of power storage. The ASU Core Research Facilities house numerous pieces of specialized equipment and expert staff that support battery research and development, from fabrication to testing.

Eyring Materials Center

EMC proudly supports the AMPED initiative, contributing to the acquisition of advanced technologies like Sigray, PrismaE SEM, CleanMill and air-sensitive XPS holders.

These enhancements, made possible through AMPED funding, highlight EMC's commitment to fostering innovation within our community.

EMC supports the AMPED STC batteries initiative by offering a diverse array of instrumentation.

STOE STADI P transmission X-ray diffractometer

Measurements in operando during battery operation. It assesses crystallinity, identifies present phases and pair distribution functions.

X-ray Photoelectron Kratos Axis Supra+

Provides surface chemistry insights with two air-sensitive sample options.

Equipped with air-sensitive sample holders, analyzes battery materials, revealing domain size, crystallography.

Rigaku SmartLab X-ray Diffractometer

For samples that are less air-sensitive or suitable for analysis in air.

Uses a fingerprint technique to identify materials based on vibrations. Its sensitivity gives information on composition and strain.

Electron Microscopy

CleanMill ion beam polisher paired with the Clean connect transfer system ensures air-free sample transport from the ion polishing instrument to the new Prisma E SEM.

Prisma environmental SEM, installed in December 2023, will be available for general SEM imaging as well as imaging of samples loaded via the air free transport ensuring no surface change due to interaction with air.

TEM also offers multiple battery material analysis options, available at both ambient and cryogenic temperatures

How EMC supports materials science.

Advanced Electronics & Photonics

The Advanced Electronics & Photonics (AEP) Core Facility has several pieces of equipment that can be used in the characterization and processing of Batteries.

|

The Keyence VK-X3000 Laser Confocal Microscope performs nanometer-scale topology, surface mapping, profiling of sidewalls and has the capability to detect birefringence.

Battery Characterizing and Processing Equipment

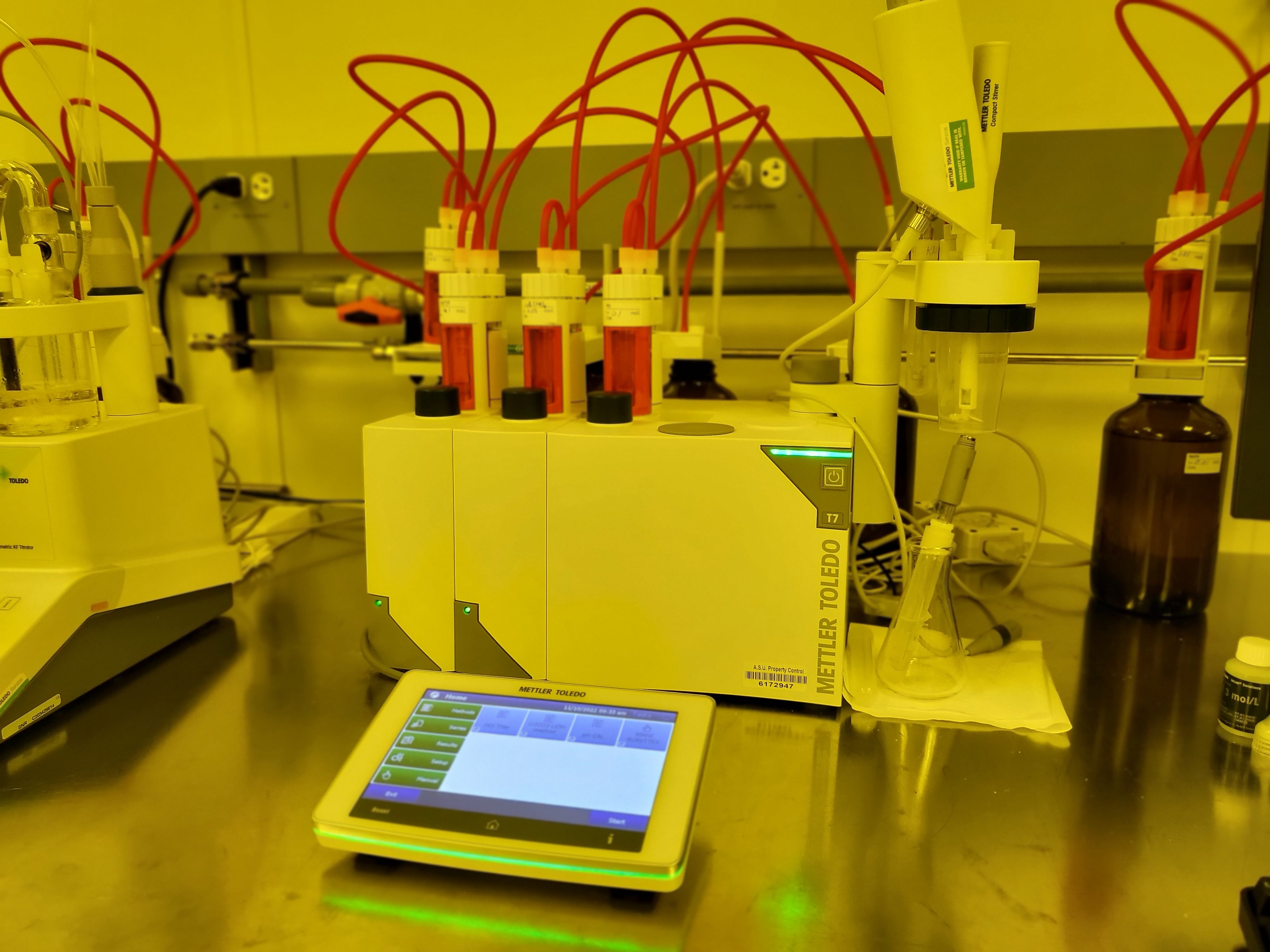

Mettler Toledo Titration Equipment

Determines the amount of a substance. The chemical reaction is monitored either by color change with a photometric sensor, a suitable pH, redox, conductivity or surfactant sensor.

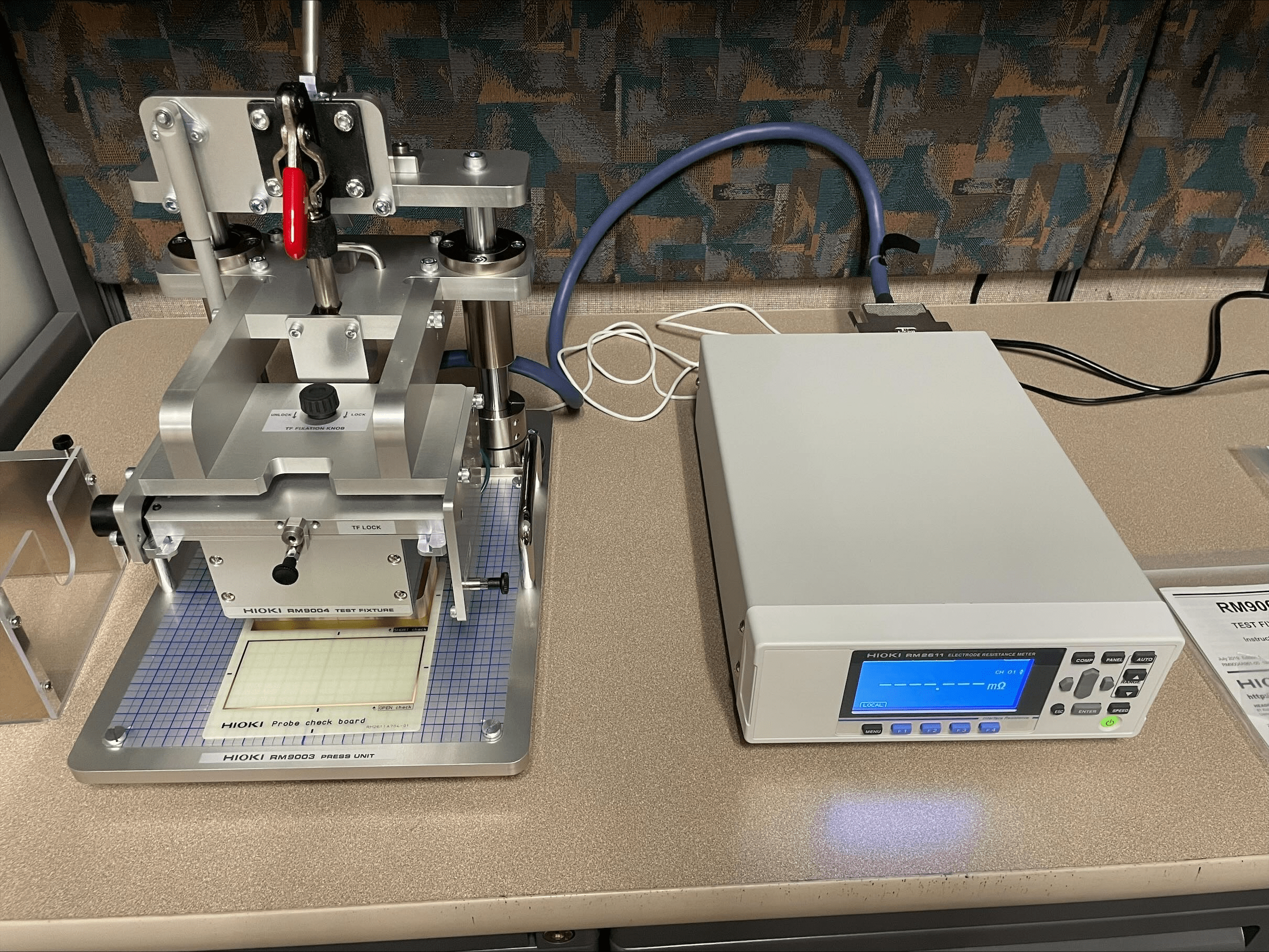

Hioki RM2610 Electrode Resistance Tester

Consists of the RM9003 Press, RM2611 Meter and control software. The system isolates and quantifies composite layer and interface resistance in positive and negative electrode sheets used in lithium-ion-batteries.

Thinky ARE-310 Centrifugal Mixer

Equipment with battery device manufacturing capabilities

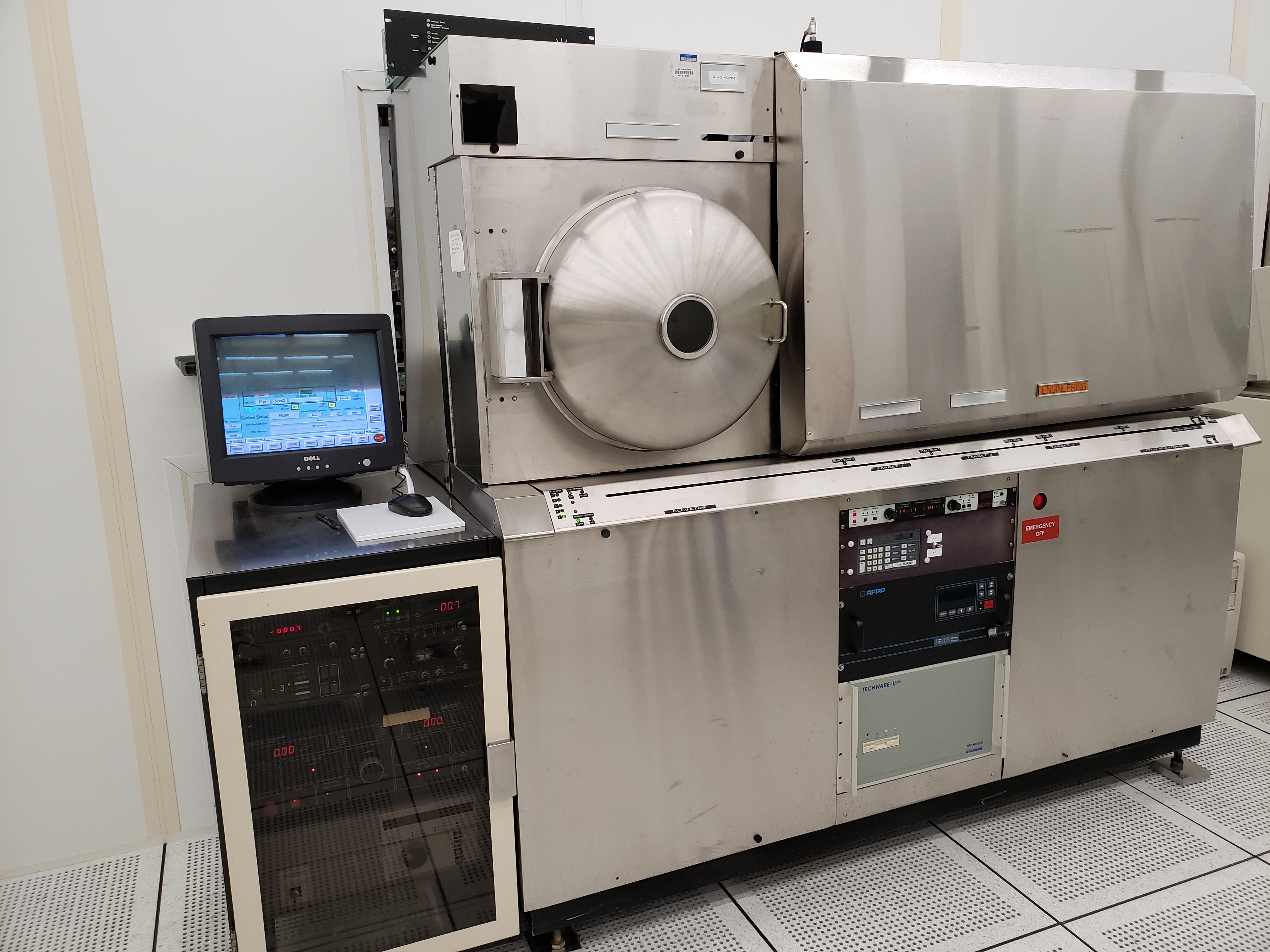

Dedicated to non-silicon processing with 4 evaporation pockets. No substrates pieces are being too small or too big given a wide range of materials to choose from.

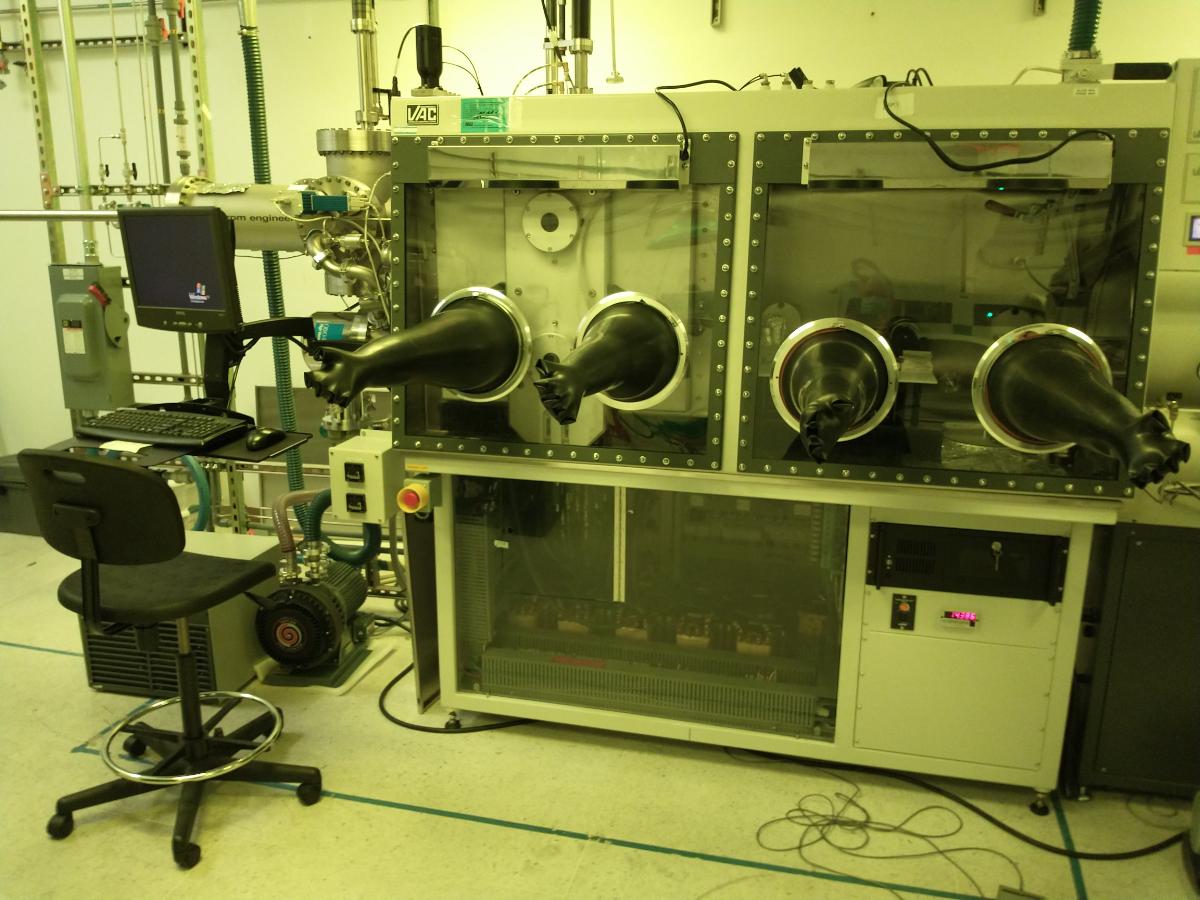

Angstrom Glovebox Evaporation Deposition

Housed in a nitrogen glovebox, the spin coater is employed for perovskite spin processing and the evaporation chamber, features 11 pockets for metal and organic sources.

A vacuum system which uses argon and oxygen ionized in a plasma to impact a metal or ceramic “target”. MRC can be fixtures to fit any currently available solar cell substrate.

Metrology equipment for wide band gap and power devices

Woollam Ellipsometer M2000 measures the change in the polarization state of light as it is reflected off the surface of the film under analysis and its substrate.

TA Instruments HR-20 Rheometero: Measures viscosity of a mixture. Used on battery electrolyte and electrode mixtures to verify run-to-run consistency.

Optical characterization equipment: Flexus stress gauge, Thermo Nicolet 6700 FTIR, RPM-2000 Photoluminescence.

Physical characterization equipment for measuring surface roughness or topology: Park XE-150 AFM and Tencor P-16 Profilometer.

How AEP supports battery and microelectronics R&D

Solar Fab

The Solar Fab Core is nearing completion of the installation and initial operation of two Atomic Layer Deposition (ALD) Systems. ALD is a technique used to accurately coat substrates with thin films through a controlled, sequential exposure to various precursor materials.

ALD will be instrumental in improvement of Battery interface stability, necessary to enable ultra fast charging for both Li-ion and solid-state batteries.

Veeco Fiji ALD

A plasma and thermal ALD compatible with 200 mm semiconductor substrates.

Veeco Savannah ALD

A thermal ALD system compatible with 300 mm semiconductor substrates.

How Solar Fab helps ASU advance clean energy research.

News

Arizona Commerce Authority will allocate the funding to purchase equipment to enhance the capabilities of ASU’s MacroTechnology Works (MTW) in Tempe

ASU plans to expand advanced packaging and GaN research to additional capabilities that support 6G, IoT, machine learning and more. The expansion will also include workforce development initiatives such as internships and university joint research and next-gen GaN research development for 6G in partnership with NXP Semiconductors in Chandler.

Explore ASU's manufacturing expansion plans.

Publications

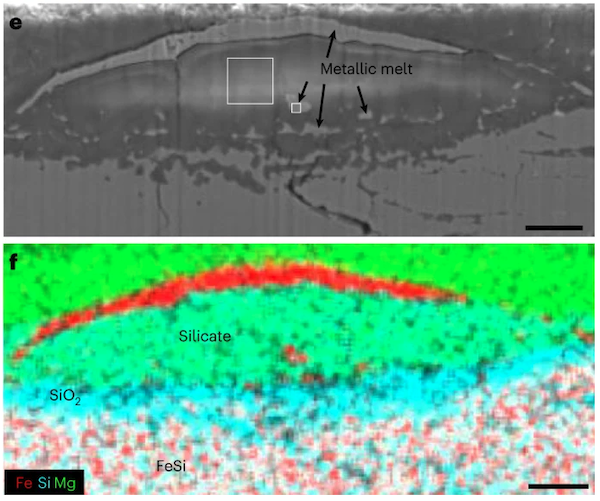

A hydrogen-enriched layer in the topmost outer core sourced from deeply subducted water

We're proud to acknowledge that some of this groundbreaking research utilized resources from Arizona State University's METAL Core, showcasing the impact of our facilities on global scientific advancements.

Abstract

The researchers' experiments reveal that water interacting with Fe–Si alloys under core–mantle boundary conditions produces SiO2 and FeHx, potentially explaining the distinct properties of the Eʹ layer and indicating a long-term chemical exchange between Earth's core and mantle.

Method

The Earth's outer core is 10% less dense than pure iron-nickel alloy, suggesting the presence of lighter elements. Our study focuses on a new hydrogen-silicon exchange process at the core-mantle boundary (CMB), shedding light on the Eʹ layer's formation and the development of chemical heterogeneities.

Results

Water from minerals reacts with Fe–Si, hydrogenating iron and oxidizing silicon into silica, which may transform ferropericlase into bridgmanite or post-perovskite.

Delve into the researchers' findings